1. What are Applications EAGLE Industrial Calibration Weights used for?

EAGLE calibration weights are used for verifying and calibrating weigh bridges,truck scales, crane scales, pallet scales, and other high-capacity weighing systems. They ensure measurement accuracy and compliance with legal meteorology standards.

2. What material are these calibration weights made from?

They are manufactured using high-strength mild steel with protective coatings to withstand industrial environments and heavy-duty usage.

3. What accuracy class do these weights belong to?

EAGLE calibration weights are available in M1 accuracy class, suitable for commercial and industrial calibration applications that require reliable precision.

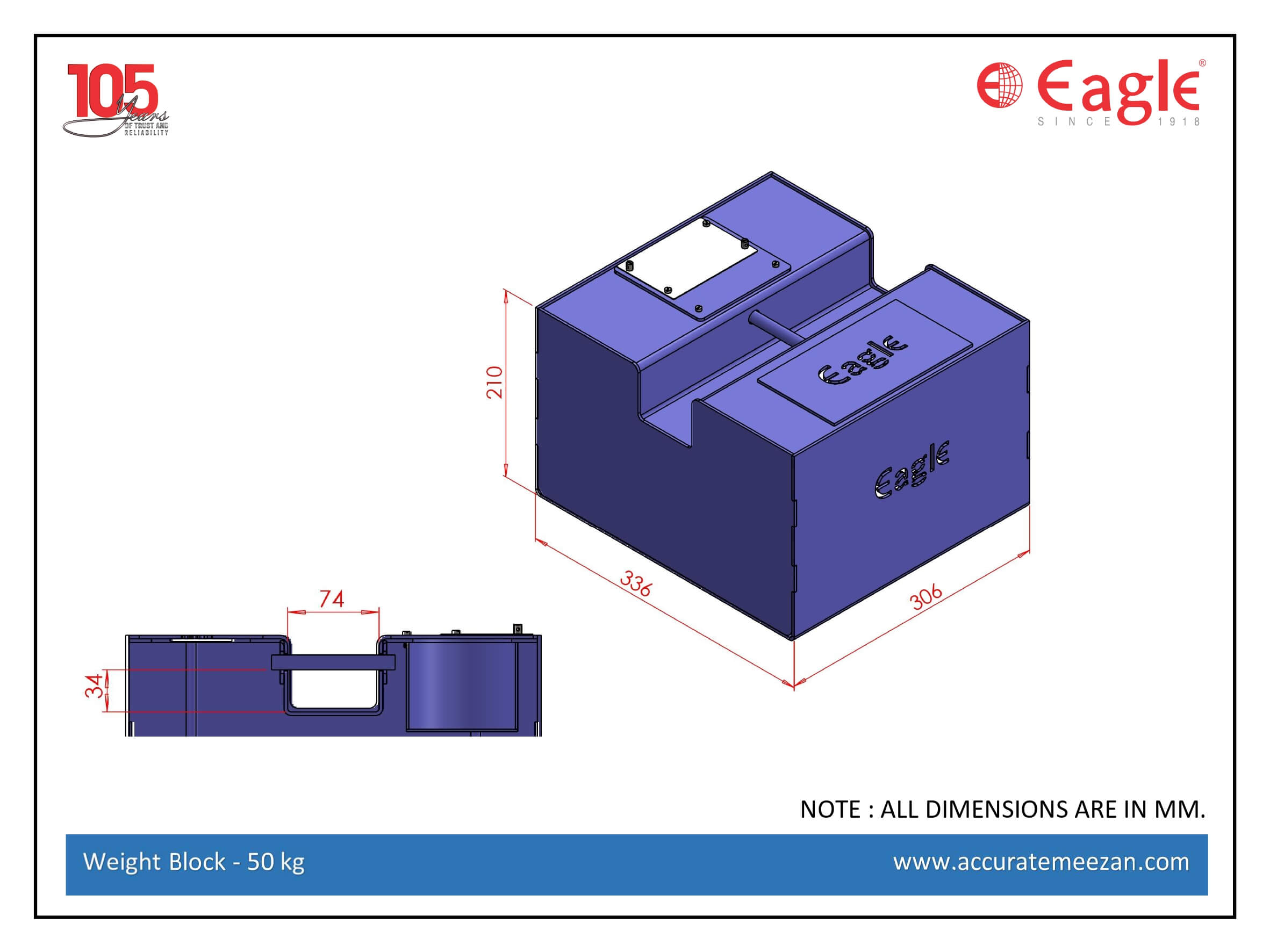

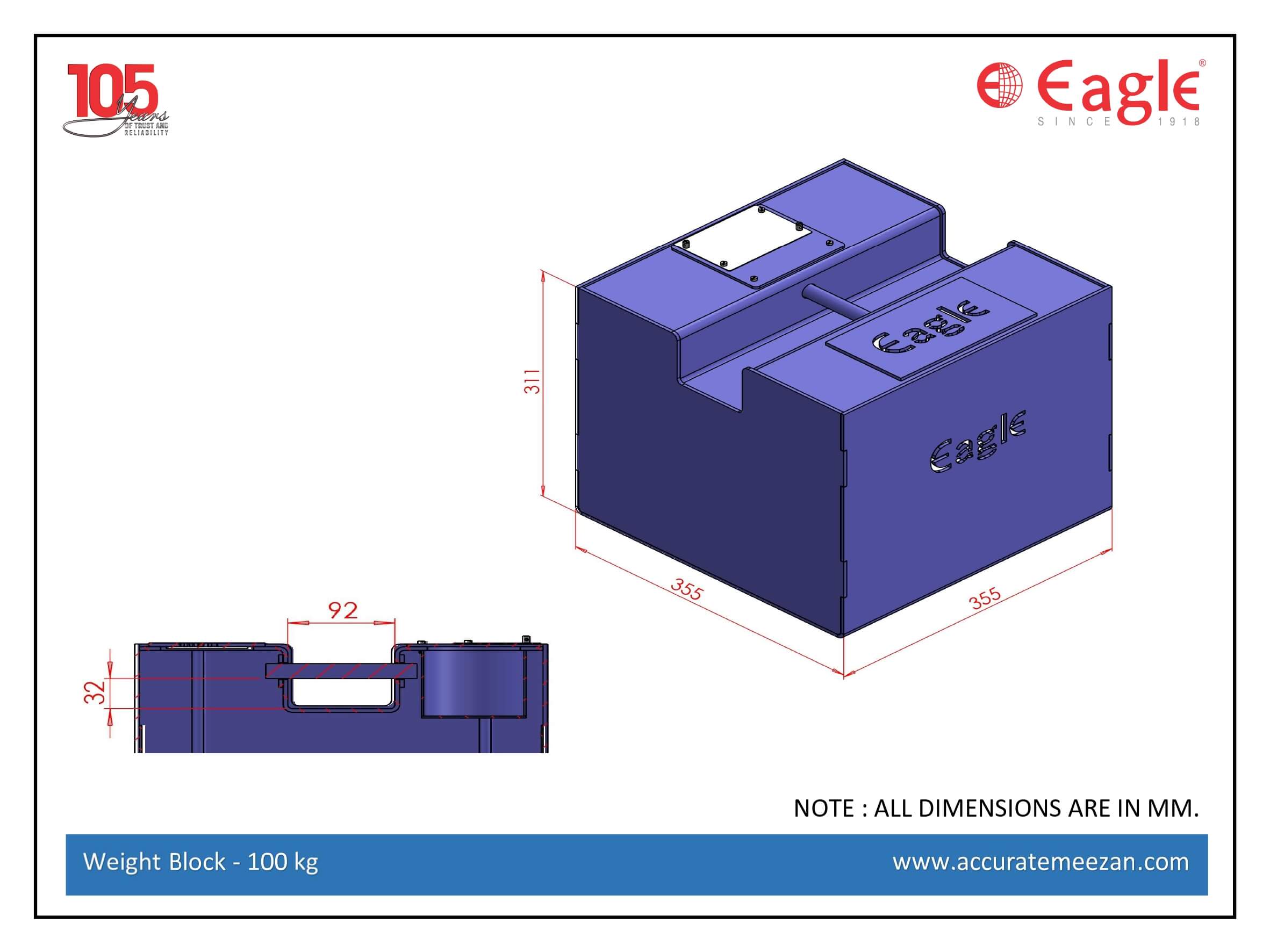

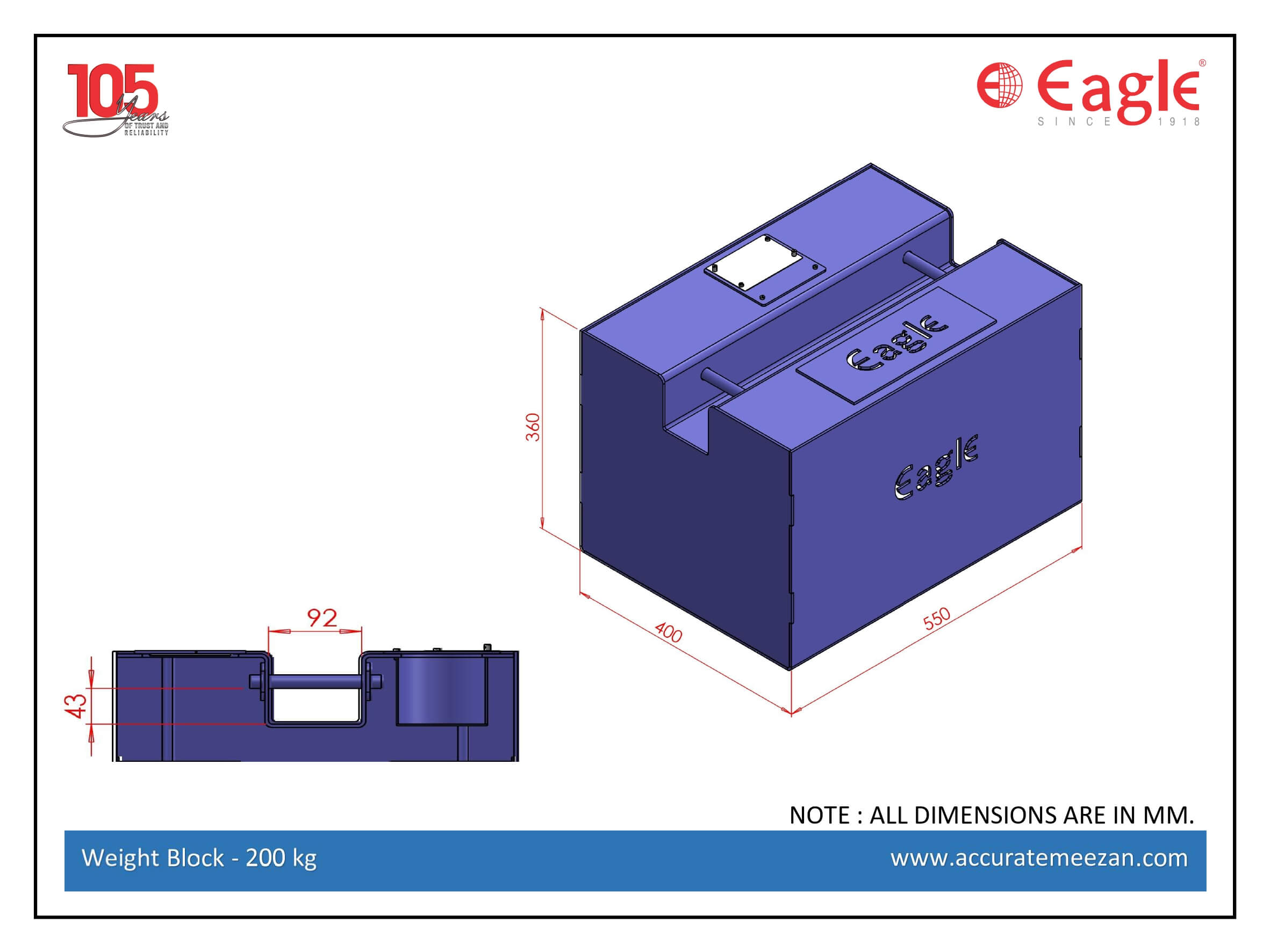

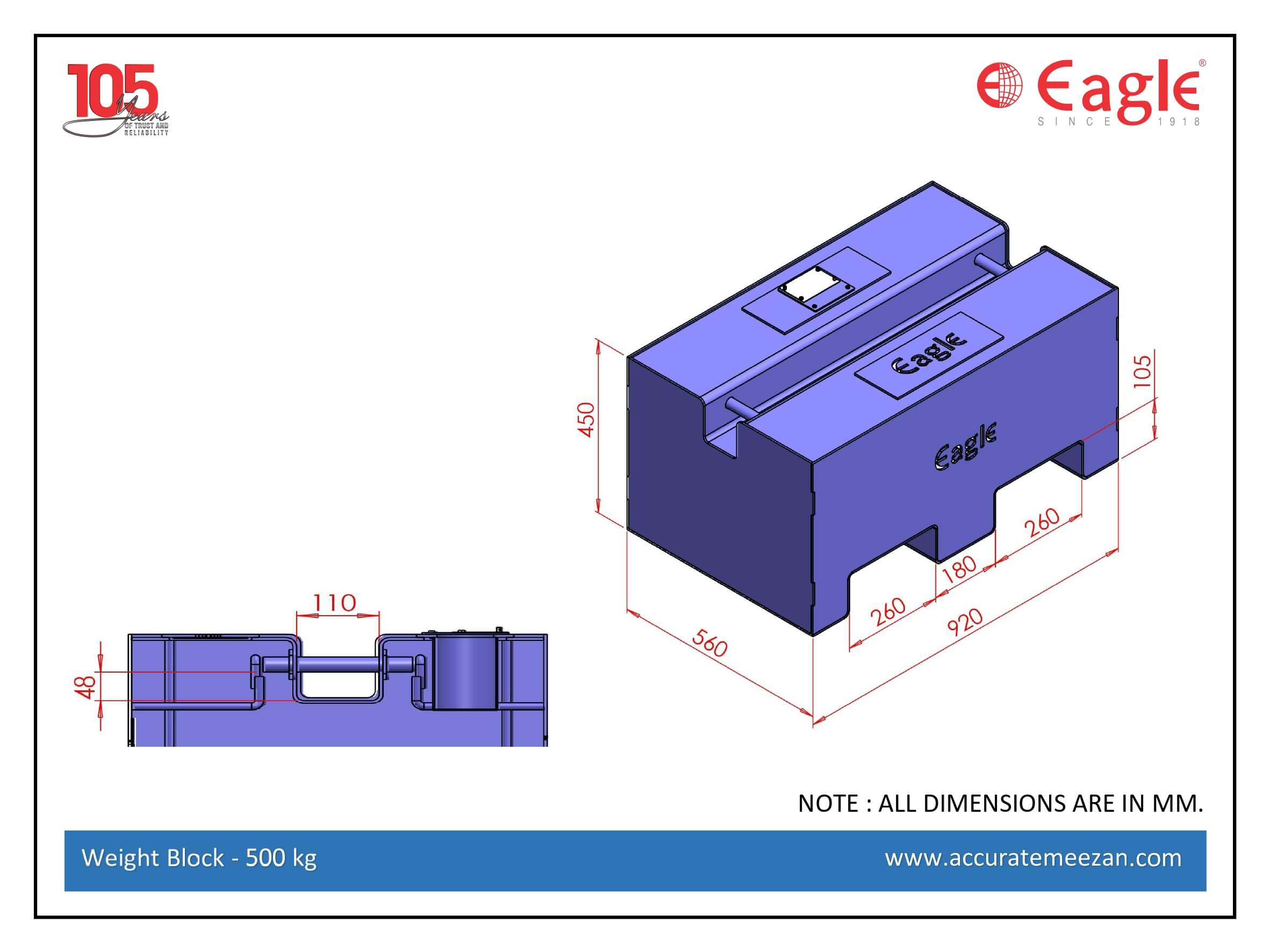

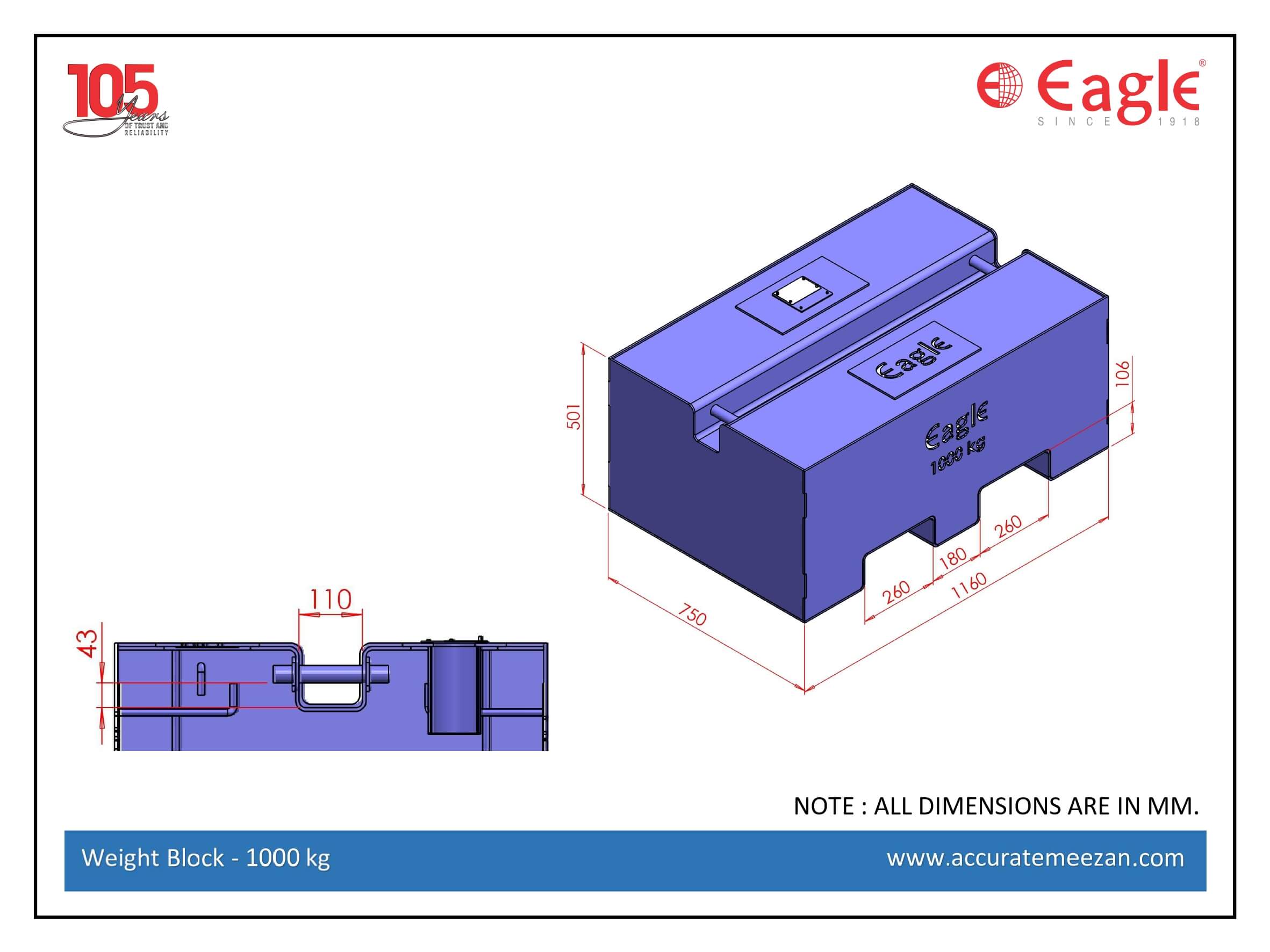

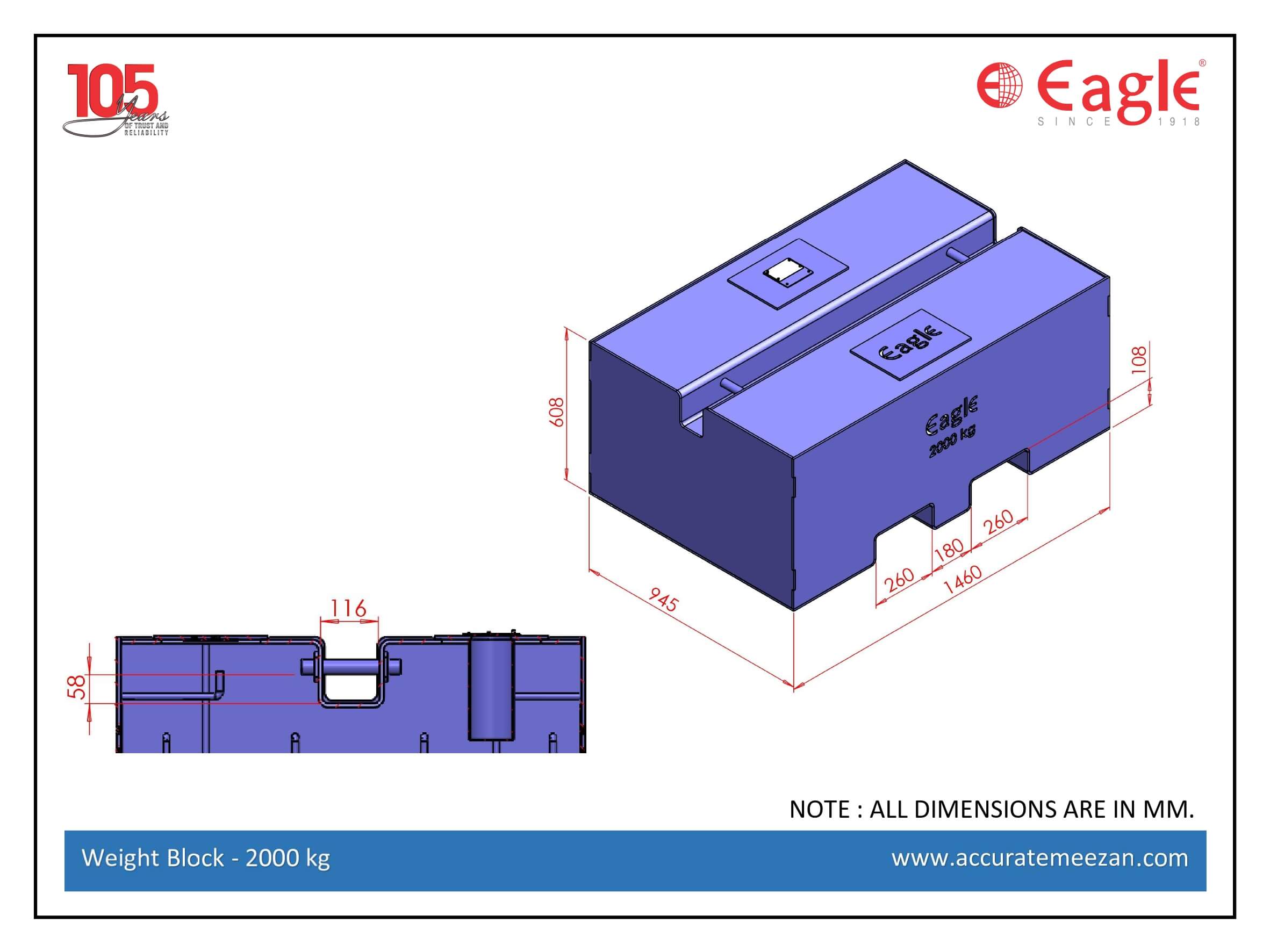

4. What weight options are available ?

EAGLE offers weights in the following capacities:100 kg, 200 kg, 500kg, and1000 kg, suitable for both small and large-scale calibration requirements.

5. Are these calibration weights certified ?

Yes. Each weight is supplied with the necessary calibration certificates ensuring traceability and adherence to national and international standards.

6. How can these weights be handled on-site?

These weights are designed with a built-in lifting rod, allowing safe handling using cranes, forklifts, and stackers, even in rugged industrial environments.

7. Can these weights be used for weighbridge stamping and verification?

Yes. The M1-class weights are suitable for official verification, stamping, and performance testing of weighbridges as per legal metrology guidelines.

8. How often should weighbridges be calibrated using these weights?

It is recommended to calibrate weighbridges every 3–6 months, depending onsite usage, environmental conditions, and regulatory requirements.

9. Are these weights suitable for outdoor use?

Yes. They are coated with weather-resistant protective finishes, making them suitable for outdoor installations and transportation.

10. Can these weights be customized as per special requirements?

Yes, customization such as logos, serial numbering, special coatings, and weight configurations can be provided on request.

11. Do they support ISO and audit compliance ?

Yes. EAGLE calibration weights come with certified documentation, making them compliant for ISO audits, internal quality checks, and third-party inspections.

12. How are these weights transported safely ? -

Depending on quantity and size, they are transported using :

A. Wooden pallets

B. Metal cages

C. Forklift-compatible frames

This ensures safe movement and prevents damage.