The market for packing machinery is a dynamic one that is full of innovation and change. It is also susceptible to inflation, supply chain, trade, and geopolitical disputes. The packaging machine industry is implementing innovative and long-lasting strategies to improve product packaging’s environmental, consumer, and brand-and packaging-related friendliness.

Introduction

Active Packaging, the internet of Packaging, and nanotechnology are the major packaging industry machinery trends that make smart packaging possible. As a result, innovations in edible, recyclable, and biodegradable packaging are accelerated by startups and scale-ups. In the same way, consumer businesses save money and simplify packaging procedures by using robotic packaging and 3D printing.

Let us now discuss some of the major Innovations in Packing Machine Technology and how they improve packaging Processes.

What are the innovations in packaging machine technology?

- The internet of packaging:

By introducing customers to various product content, discount codes, and video tutorials, augmented reality packing gives businesses a chance to better engage with customers. The Internet of Packaging disrupts traditional packaging technology and enables consumers to better connect with brands. Near Field Communication (NFC) chips, QR codes, smart labels, and RFID are examples of technologies used in smart packaging.

Eagle’s cutting-edge solutions transform your product packaging into a data carrier and digital tool, providing connectivity, authentication, and security benefits that add value. Additionally, IoT devices enable brands to incorporate diagnostic and indicator functions into their packaging, providing customers with real-time information regarding the product’s condition.

2. Biodegradable Packaging

The machinery and packaging materials environmental impact worldwide has been a major source of concern. Plastic pollution and climate change are growing concerns. Green packaging materials that are recyclable and less polluting are increasingly in demand. However, making a fundamental change to the packaging configuration or material often necessitates purchasing expensive new equipment.

Since the beginning of the 20th century, plastic has been the most widely used material for packaging. However, environmental issues are widespread due to their slow decomposition rate. Films and packaging that break down into biodegradable materials are gaining popularity and are suitable alternatives to plastic Packing machines. Businesses can adopt these innovations slowly and lessen the packaging machines industry’s environmental impact.

3. Automation of Packaging

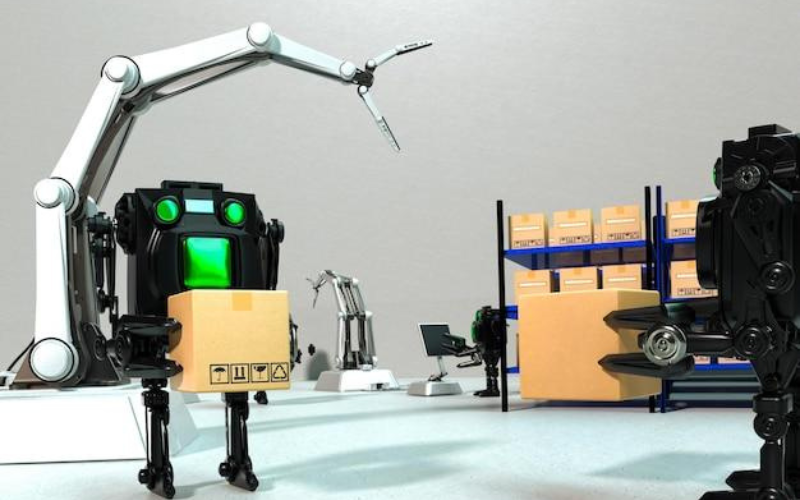

Productivity, precision, and quality control are the main challenges of Packaging machinery. A major trend in the packaging industry machinery is to automate the processes of depinning, filling, packing, and palletizing. Using robotic arms and grippers, our packing automation machines, such as the automatic strapping machine, prevent human error and ensure the safe handling of delicate products.

Last but not least, startups create AI-powered vision systems that take pictures of finished goods to evaluate the quality of the packaging. These vision-assisted robots automate product sorting, quality control, and inspection to improve overall efficiency.

4. Robotics

The packaging machinery industry is likely to grow due to robotic packaging’s rising popularity. Technological advancements are pushing the capabilities of robots toward primary packaging, which includes pick-and-place operations, applications for cartooning, and processing tasks like coating and cutting. The packaging industry’s labor savings have prompted the use of robotics.

Robotic packaging automation imitates human movements to remove humans from the process without sacrificing output. Using robotic packaging automation from Eagle, your business can expand operations with accuracy and consistency while simultaneously reducing staff injuries.

The most significant advantage of robotic packing automation is that it will free your employees from the monotonous and frequently risky tasks they had previously performed. As a result, they will be able to acquire new skills and contribute to the company’s expansion. Many businesses can reap the benefits of robotic packaging automation’s improved supply chain process, increased packaging efficiency, and decreased operational costs.

5. Custom Packaging

In many countries and markets, packaging machinery manufacturers are working to create the next age of machines to place themselves for future success. The increased focus on technological innovation has become a leading competitive factor. Companies are investing in artificial intelligence, advanced software, and other cutting-edge technologies, which will continue to accelerate technological innovation in the global packaging machinery industry.

A product’s appearance significantly impacts how consumers respond to it. As a result, as a marketing tool for businesses, the packaging is just as important as the product itself. To increase sales, the brands face the challenge of making the packaging stand out. As the number of businesses offering advanced custom packaging machinery grows, the incorporation of advanced technologies from sensors to software will pick up and become more widely available.

The key to making the unboxing experience more personalized and one-of-a-kind is to make a lasting impression on customers and encourage them to return to the brand. Companies will roll out new packaging equipment that is more capable, more efficient, and even safer in some cases, depending on what they are trying to accomplish, as a result of the need for greater customization.

6. Edible Packaging

Businesses and consumers alike have been shifting their focus toward environmentally friendly packaging. As it adheres to the use-dispose model, packaging significantly contributes to solid waste and ends up in water bodies or landfills. Businesses face the challenge of selecting packaging that meets this fundamental requirement and eliminates or reduces solid waste.

The edible packaging machine is a revolutionary trend in the packaging machine industry that addresses these issues and makes it possible for the packaging to have a closed loop. A good illustration is casein-coated food product packaging made from milk protein. In comparison to plastic, these packages are better at keeping meals fresh. Also, companies that make edible straws, spoons, and other cutlery offer plastic alternatives to chain restaurants, cafes, and ice cream parlors.

7. Printing 3D

The growing trend in the packaging industry is 3D printing, which enables businesses to construct various prototypes and innovate their packaging line almost immediately. Packaging design experiments are costly, time-consuming, and wasteful for brands. These issues are mitigated, and personalized packaging is made possible by 3D printing or labeling technology packaging machines without contributing any plastic waste.

Engineers and designers now have more creative leeway to create high-quality products thanks to this technology. Manufacturers also use additive manufacturing technology to create prototypes of parts for packaging machinery, such as robotic arms printed for a specific packaging line or Eagles’s wrap-around labeling machine.

This is used for pharmaceutical labeling, inhalers, tablet tubes, cosmetics, food, and confectionery labeling, from cereals in cans to jam in jars, labeling home goods in various forms, labeling chemical products as well as cartridges, and many more.

8. Nanotechnology

Nanotechnology has applications at various stages of the packaging supply chain, including product safety, authentication, tracking, and packaging material. Combining nanoparticles with polymer chains increases your package’s tensile strength and barrier properties. Brands and packaging companies can also use it to track products and fight counterfeits.

Additionally, nanotechnology packaging machines address the growing concern about food safety, which significantly impacts the food packaging industry. The surface of the packaging is protected from dirt, dust, and stains by applying nano-coating. Lastly, various nanosensors are useful for detecting chemical changes and monitoring food freshness.

Conclusion:

Modern packaging machines offer numerous advantages in today’s technical-driven environment that boost business innovation. The industrial advancements made possible by these cutting-edge machines and equipment are unparalleled. A business or industry relies on revolutionary technology primarily to increase employee productivity.

We at Eagle always aim to provide our customers with the latest technology and solutions for all their problems. Our packaging solutions combine our extensive expertise with the latest technological incorporation to help you improve packaging processes. Get in touch with us immediately to determine which packaging option would work best for your business.

0 Comments